By Ted Beyer

Educational Innovations has carried Wilesco model steam engines off and on for years. But why? They’re just toys, right? Well, no—they are so very much more.

If you apply some critical thinking to a steam engine and its accessories, you will discover that you have a wonderful practical demonstration of a bunch of scientific principles, many of which are pretty basic.

My personal favorite is energy conversion—although we’ll run into some other principles along the way.

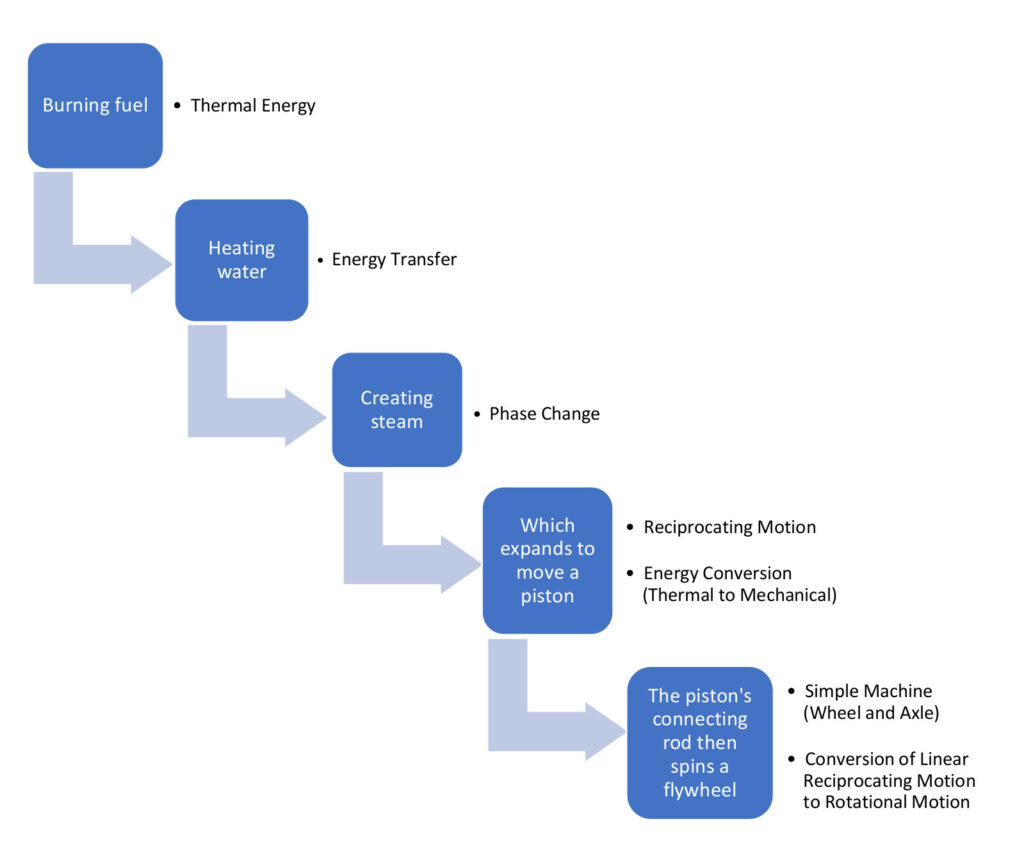

Consider all the processes caused by the Wilesco steam engine:

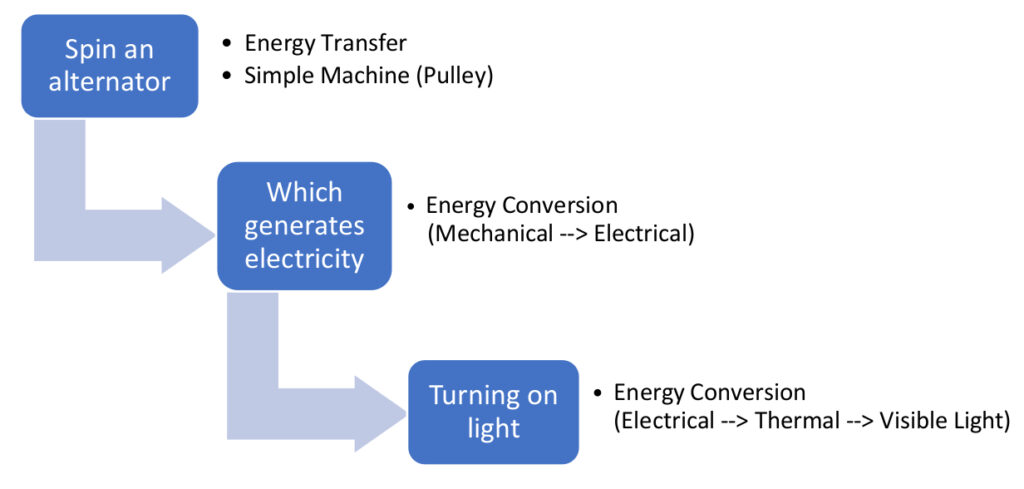

Then, if we have hooked up the right accessory, we can take it even further:

And let’s not forget another phase change as the steam condenses back into water vapor, and ultimately returns to liquid water after it leaves the piston.

Of course, there are also many other simple machines being demonstrated here—levers, wheels with axles, and pulleys (when using accessories).

I am sure I missed two or three (or four or five) conversions and machines in there—especially if you have a more complex steam engine at your disposal.

How many more can you find?

Wilesco in Action

Our selection of Wilesco steam engines is unparalleled, so it’s not easy to choose a “typical” video. But this one covers all the processes I’ve described above. Plus, it’s just really a cool video.

Some Fun Steam Engine Facts

Did you know that during the Second World War, the US Army discovered that a small model-type steam engine produced just the right amount of power to run their poison gas detectors? They became standard issue.

The largest steam locomotives ever built were the Union Pacific “Big Boys.” Only 25 were built, each weighing in at over a million pounds (453,000Kg). They generated 6,300 horsepower and could reach over 80 mph (129 kph). They were used to haul freight over the Wasatch Mountains in the American West. One of these mighty engines has been restored to working condition and tours the USA.

And a Steamy Wilesco Secret!

Shhhhhhh…. It’s a little bit of a secret, but EI is now the host and administrator of the Wilesco steam engine line in the United States. Wilesco has been making beautiful, high quality model steam engines in Germany for more than 70 years.

Since we warehouse their stock, that means that in addition to the vast selection we have on our website, we actually have access to even more products than those you see on our website—including replacement parts. If you are looking for something and don’t see it, give us a call! We may well have it on hand—and at excellent prices.

Hello Ted,

I’ve been trying to purchase a Wilesco D22 steam engine since December 2020, but your company has been out of stock. I’ve inquired a couple of times as to when you will have more and was told that they haven’t been replenished due to the shipping challenges caused by COVID. Can you provide any information as to when they might be back in stock?

Thank you,

PE

Hello Paul,

It appears that Wilesco is back up and running. I am attaching the current letter from our manufacturer in Germany.

Dear Wilesco Customers,

I’m writing to explain details of our difficult year, and to assure you that things are looking up!

Wilesco has had a bumpy year due to several factors. The main reason was a significant loss of sales at the beginning of the COVID-19 pandemic, which forced us to reduce our production capabilities in April 2020.

Happily, we returned to a regular production schedule in August 2020. At that point, we strived to meet customers’ demands for our steam engines, but these products are time intensive. It takes at least four weeks to create a batch of steam engines, from the first screw to the completed machine. We have hired additional employees to help minimize the production gap.

Another big factor which continues to hamper us is the increase in our European suppliers’ production and delivery times. This causes a delay, because we can´t build the engines without certain parts.

All in all, we are optimistic that we will be able to meet our customers’ demands in the next months.

We are trying our best in the current situation, and thank you all for your continued patience.